Why is supply chain transparency and traceability important?

Achieving transparency and traceability in supply chains is crucial for businesses that want to operate ethically, responsibly, and sustainably. By ensuring both transparency and traceability, businesses can identify and mitigate risks, meet legal requirements, and address the growing demand for accountability from customers, investors, and other stakeholders.

Supply chain transparency plays a vital role in enabling businesses to identify and address potential risks such as human rights violations, environmental damage, and reputational harm. It provides visibility into the various stages of the supply chain, allowing businesses to assess and mitigate these risks effectively. Transparency also helps ensure compliance with laws and regulations, fostering a culture of responsible business practices.

On the other hand, supply chain traceability focuses on tracking and documenting the movement of raw materials throughout the supply chain. It enables businesses to verify the origin, sustainability, and ethical production practices of their products. Through traceability, businesses can manage their environmental impact, reduce risks, and promote sustainability. By having a clear understanding of the supply chain journey, businesses can make informed decisions and build trust with stakeholders.

Combining supply chain transparency and traceability creates a comprehensive approach that strengthens the overall integrity of the supply chain. Transparency allows businesses to identify potential risks and take proactive measures, while traceability ensures that products are produced ethically, sustainably, and in compliance with regulations.

Need more information?

By contacting QIMA you agree to our privacy policy and terms and conditions.

How can QIMA support?

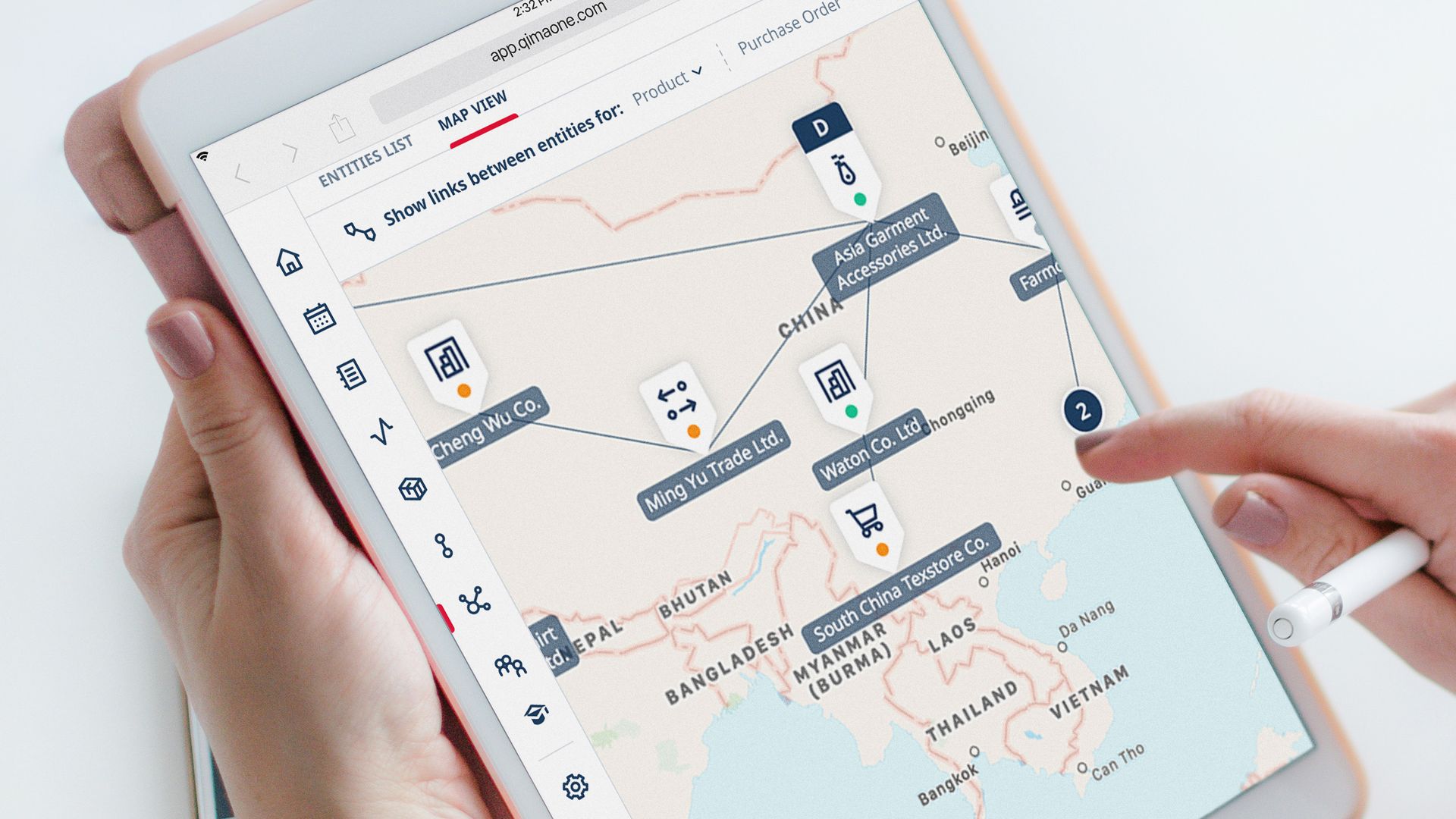

Supply Chain Mapping and SAQs: We help businesses gain visibility across all levels of your supply chain. Our process begins with supply chain mapping and setting up self-assessment questionnaires (SAQs) to collect valuable data from all tiers of your supply network. This enables you to identify and engage suppliers beyond the first tier.

PO Traceability assessment: We help develop a process of tracking and verifying the entire manufacturing process from raw material to finished products using purchase order data. This ensures compliance with regulations and standards and identifies potential risks or issues in the supply chain.

Traceability audits: Our onsite traceability audits are essential for businesses to verify their entire manufacturing process from the ground. From documentation and test reports on raw materials, production planning, sub-contractor evaluations to product identification and traceability control procedures, we ensure that your supply chain meets the necessary standards and regulations.

Material tracing: Through our innovative solutions developed by our trusted partner Haelixa, we can physically mark, trace, and authenticate products from raw materials to finished products throughout the supply chain. Material tracing is important in supply chain traceability as it enables businesses to ensure that their products are ethically and sustainably produced.

Provenance testing: Our provenance testing solutions involve analyzing the chemical, physical, and biological properties of materials to identify and verify the DNA of raw materials. By proving the origin and authenticity of raw materials, we help businesses ensure that their products were obtained from responsible sources and were not produced using harmful or unethical practices.

Contact us to learn more about how we can help your business achieve greater visibility and strengthen your ESG practices, including tracking and calculating your product's carbon footprint, across your supply chain.

QIMA benefits

Custom compliance dashboard to assess real-time ESG and supplier performance, track progress and visualize your supply network

Data downloads to map against reporting standards to support companies’ communication strategies

In-depth local knowledge with auditors attuned to the culture, laws and practices of their region

Our experts receive regular training on regulations and best practice

Global coverage in over 100 countries in Asia, Africa, Europe, North and South America

Continuous improvement approach drives long-term change and empowers suppliers to act

Online program management book audits, make payments and download detailed reports.